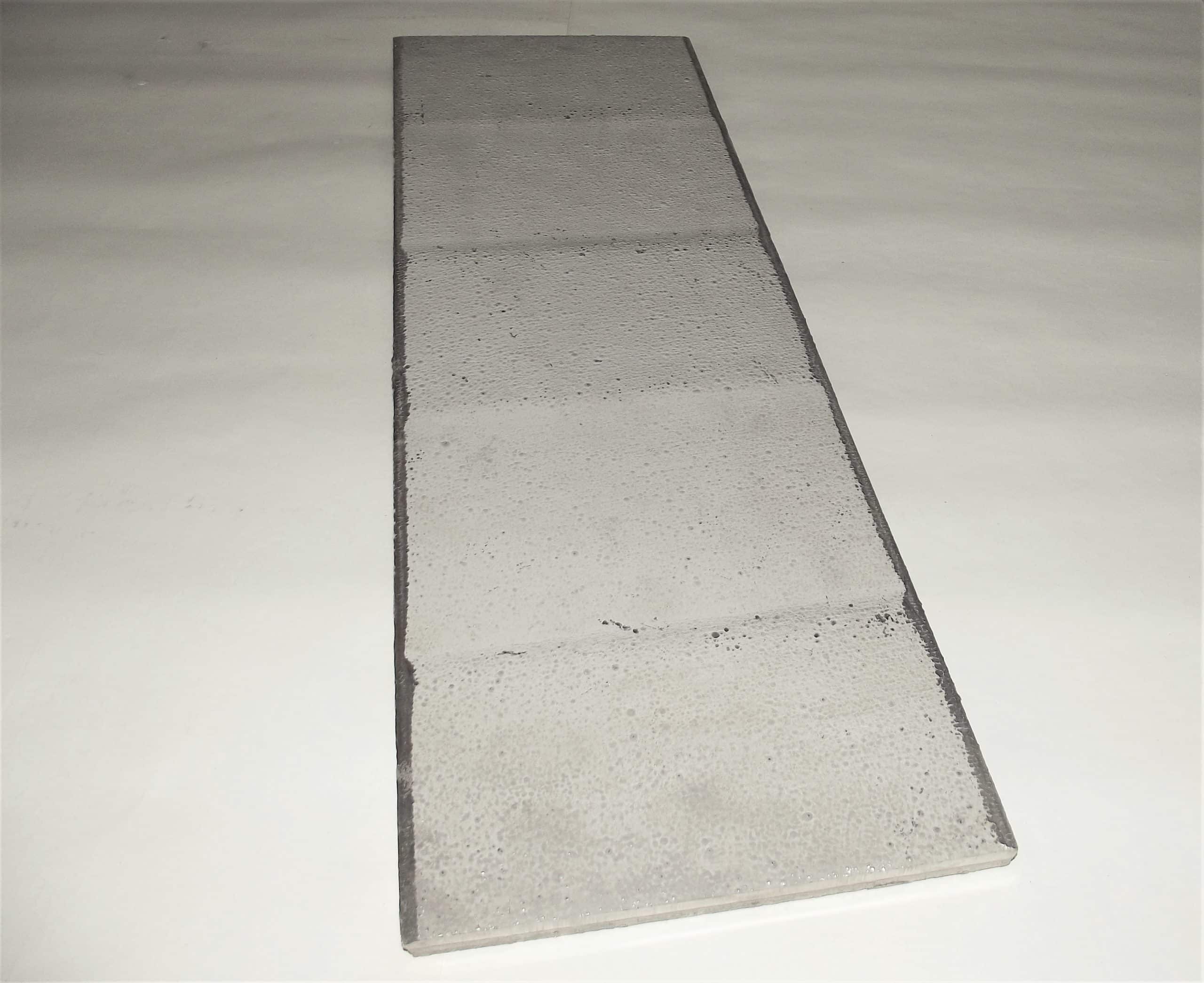

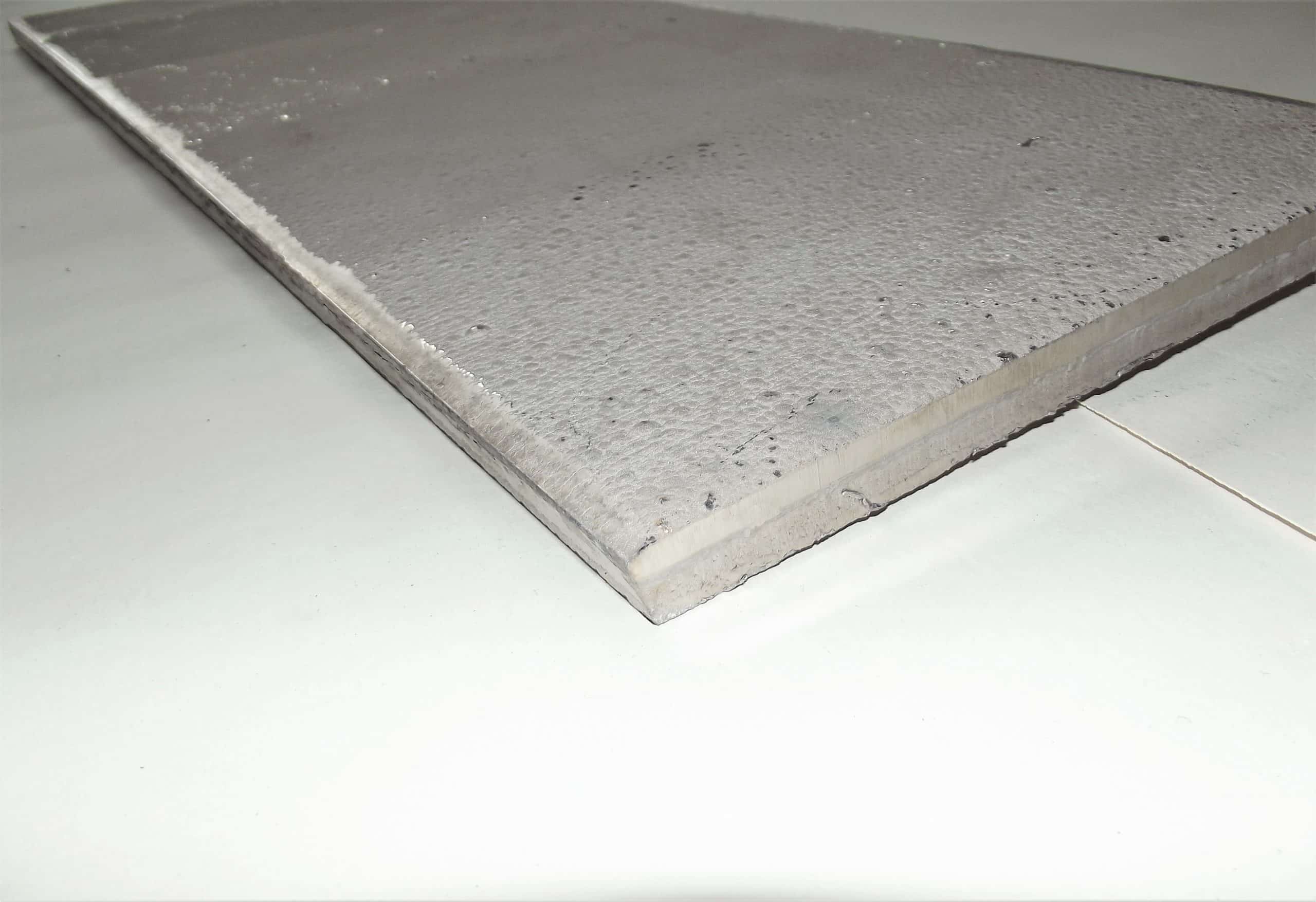

Nickel anode 200x1000x12mm 21.200kg Ni 99.98%

IMPORTANT: Buying with a valid VAT ID?

Please contact us by email: info@widerangemetals.com in order to proceed your order using the zero (0%) VAT rate.

For our clients, we are offering possibility to achieve the best results using high quality materials. You have the opportunity to buy a quality product with a wide range of uses, we believe that this nickel anode will meet all your requirements.

Place of origin: EU

Nickel Ni 99.98% min.

Weight and anode size: 21.200 kg. / 200 x 1000 x 12mm

Also we have different Ni anode sizes in offer.

Specifications of nickel anode:

Nickel : 99.98% Min

(Fe) Iron : 0.0015% Max

(Pb) Lead : 0.0001% Max

(Co) Cobalt : 0.0005% Max

(Cu) Copper : 0.0005% Max

(Zn) Zinc : 0.0005% Max

Total impurities, no more than: 0.02% Max

Nickel is mainly used to apply reliable coatings to metal, improves protection and makes attractive look.

Nickel helps not only to acquire an attractive appearance for the product, but also he provides high resistance to corrosion and also extending the service life of treated surfaces.

Application and production of anode:

Basically, nickel anodes are presented in the form of sheets. Those Ni sheets are hot rolled on special machines, such workpieces are heated before they pass through the rolling machines, operation is repeating as many times as their needed to get wanted thickness.

The most common application for a nickel anode is nickel plating – coating a surface.

If you have a special requirements: Just contact us and we will try to help you on all your questions. We working with suppliers inside and outside the European Union, we have an opportunity to offer you many more options in the field of metal anodes, also different metal forms such as metal powders.

Buying with a valid VAT ID?

Please contact us by email: info@widerangemetals.com in order to proceed your order using the zero (0%) VAT rate.

Nickel Anode For Plating

In some electronic devices, electroplating is often applied to improve longevity and better conductivity. Electroplating refers to certain metal finishing types applied on the surface using electric currents. It involves a cathode and anode, and the famous anode is the nickel anode. The process using this anode is called nickel-plating. Why nickel? Here is the explanation.

What is nickel anode?

Nickel anode is pure metal nickel formed into certain shapes. The shape can be in the form of a small coin, disk, flat bar, plate, or pellet. This anode is usually used to plate other metals or plastic. Nickel anode usually gets used up since the plating goes onto the base material, which is often called the substrate.

Nickel anode types

Based on the composition, nickel anode can be grouped into four; they are:

- Electrolytic nickel anodes: as the purest form of nickel anode, it is the most critical to electrolyte composition and anodic current density. It is because it has no depolarisers. It is often sold in small pieces or strips.

- Depolarised nickel anodes: containing few amounts of nickel oxide (<1%), it has improved anode solubility. It generates a light brown layer in normal operation. It is often available in rolled oval form,

- Duvanic nickel anodes: also from pure nickel, it is added by a small amount of carbon (<1%). In a normal operation, the formed layer is porous black. This anode is usually supplied in a cast or rolled format.

- ‘S’ nickel anode: this variation contains a small amount of sulfur (<0.02%). Compared to other types, this is the type that is suitable for most nickel-plating solutions and has various shapes like rounds, strips, pellets, and others.

Nickel anode application

As nickel anode has excellent corrosive resistance, it is also used as plating in electronics, coinage, automotive, plastic, aircraft maintenance, and even aerospace. Not only to corrosion but also resists heat and wear. This anode serves functional and decorative applications. It also gives a final touch that is appealing, lustrous, and bright.