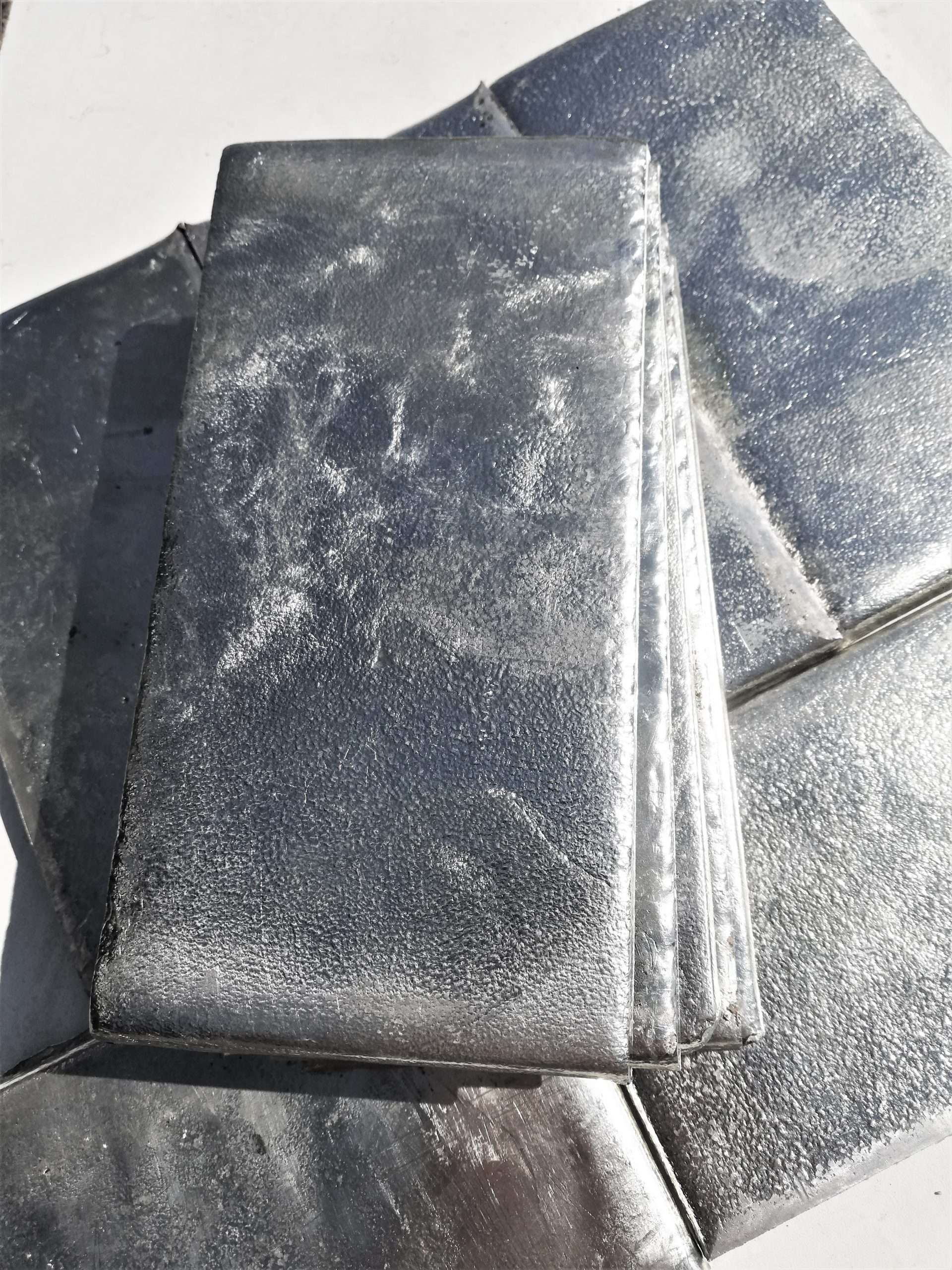

Tin metal anode 100x200x10mm 1.550kg Sn min 99.9% tin ingot metal plate

IMPORTANT for EU clients: Buying with a valid VAT ID?

Please contact us by email: info@widerangemetals.com in order to proceed your order using the zero (0%) VAT rate.

Tin metal anode 100x200x10mm

For our clients, we are offering possibility to achieve the best results using high quality materials. You have the opportunity to buy a quality product with a wide range of uses, we believe that this tin metal anode will meet all your requirements.

Place of origin: EU

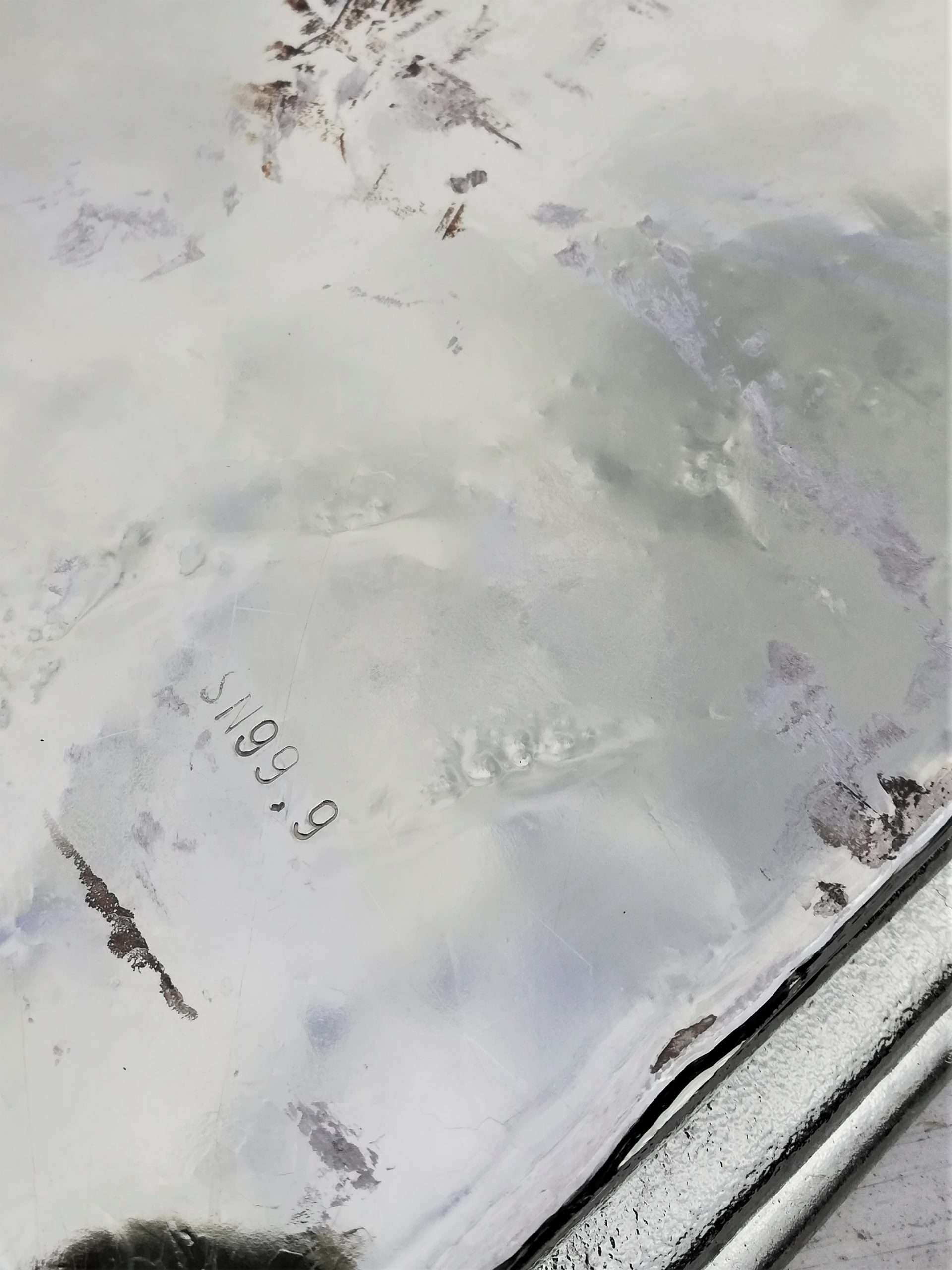

Tin anode Sn 99.9% min.

Weight and anode size: 1.550 kg. / 100 x 200 x 10 mm

Specifications of tin anode:

Tin (Sn) 99.9%

(Cd) Cadmium : 0.0001% Max

(As) Arsenic : 0.0001% Max

(Al) Aluminium : 0.0001% Max

(Bi) Bismuth : 0.0001% Max

(Sb) Antimony : 0.0140% Max

(Fe) Iron : 0.0002% Max

(Pb) Lead : 0.0003% Max

(Cu) Copper : 0.0004% Max

(Zn) Zinc : 0.0002% Max

The tin anode is in demand when carrying out anti-corrosion protection.

It is used most often in metallurgy. for electroplating, where a tin layer is electrochemically applied to the surface of metal products.

The tin anode is also can used in electronics for the production of printed circuit boards.

Tin does not emit substances harmful to humans, even under the influence of high temperatures, which makes it safe material.

Therefore, tin plating can be used in food packaging, the protective layer which is not destroyed under the influence of organic acids that are present in food.

Coating plastic and withstand deformation.

Tin-treated products have a beautiful appearance. Tin plated items are often used in decor.

If you have a special requirements: Just contact us and we will try to help you on all your questions. We working with suppliers inside and outside the European Union, we have an opportunity to offer you many more options in the field of metal anodes, also different metal forms such as metal powders.

Buying with a valid VAT ID?

Please contact us by email: info@widerangemetals.com in order to proceed your order using the zero (0%) VAT rate.

The Process of Tin Metal Plating in Corroding Objects

Tin metal can be found on aluminum foil, food packaging, food cans, automotive components, electronics, home decors, jewelry products, just to name a few. Tin is one common chemical element we use daily that is used in a mixture with other metals.

Tin metal is used to prevent corrosion on objects because it is rust resistant. For example, iron coated with tin will not corrode because there is no contact with oxygen / air and water. However, tin coating can only protect iron as long as the plating is intact, without any defects.

What is Tin Metal Plating?

Tin metal plating is the process of coating a layer of tin on the surface of other metals, such as copper or brass. As has been mentioned, tin plating is significant in terms of protecting and preventing objects from rusting.

Take for example, packaging cans, they are made of iron coated with tin metal. Tin plating is done by electrolysis solution. However, if the tin layer is damaged, then the tin metal actually accelerates the corrosion of the iron. This happens when the reduction potential of iron is more negative than that of tin.

Therefore, iron coated with tin metal will form an electrochemical cell with iron as the anode. For this matter, tin metal promotes the corrosion of iron. Thus, iron coated with tin will avoid the oxygen content in the air as a trigger for corrosion reactions.

Visit widerangemetals.com now for the opportunity to find your tin metal anode needs for plating. You will find your metal needs in a variety of sizes and weight. You may also contact their website for further information on your special inquiries.